Different Ways to Measure Water with a Flow Meter

- News

Water flow measurement is essential across many industries — from municipal water supply and wastewater treatment to agriculture, manufacturing, and environmental monitoring. Selecting the right flow meter depends on several factors: the accuracy required, pipe size, flow range, budget, and the condition of the water (clean, dirty, pressurized, etc.). In this blog post, we’ll explore…

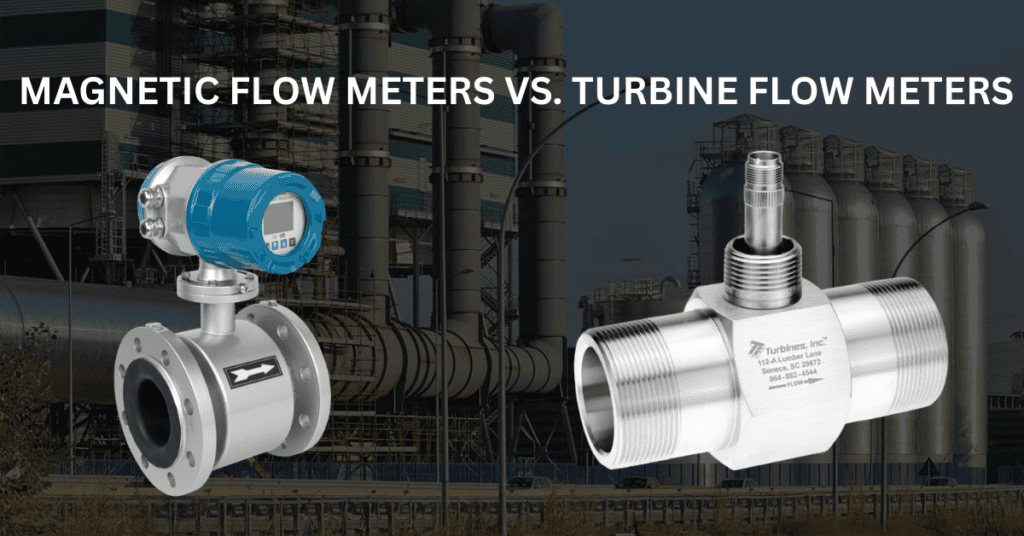

Magnetic Flow Meter vs. Turbine Flow Meter Differences

- News

Choosing the right flow meter can make a significant impact on process efficiency, accuracy, and long-term maintenance. Two of the most common types used across industries are magnetic flow meters and turbine flow meters. While each has its own strengths and limitations, understanding the differences between them can help ensure you’re selecting the best technology…

How To Pick The Right Flow Meter

- News

When it comes to measuring flow in your process—whether it’s water, gas, oil, or slurry—choosing the right flow meter is critical. The wrong choice can lead to inaccurate readings, inefficient processes, lost product, and higher costs. The right one? It gives you accuracy, reliability, and long-term performance. But with so many flow meter types out…

5 Signs Your Flow Meter Needs Maintenance or Replacement

- News

Flow meters play a vital role in many industries, from oil and gas to water treatment and food processing. They provide accurate measurements that keep systems running safely and efficiently. But like any mechanical or electronic equipment, flow meters can wear down or drift out of spec over time. Recognizing early warning signs can help…

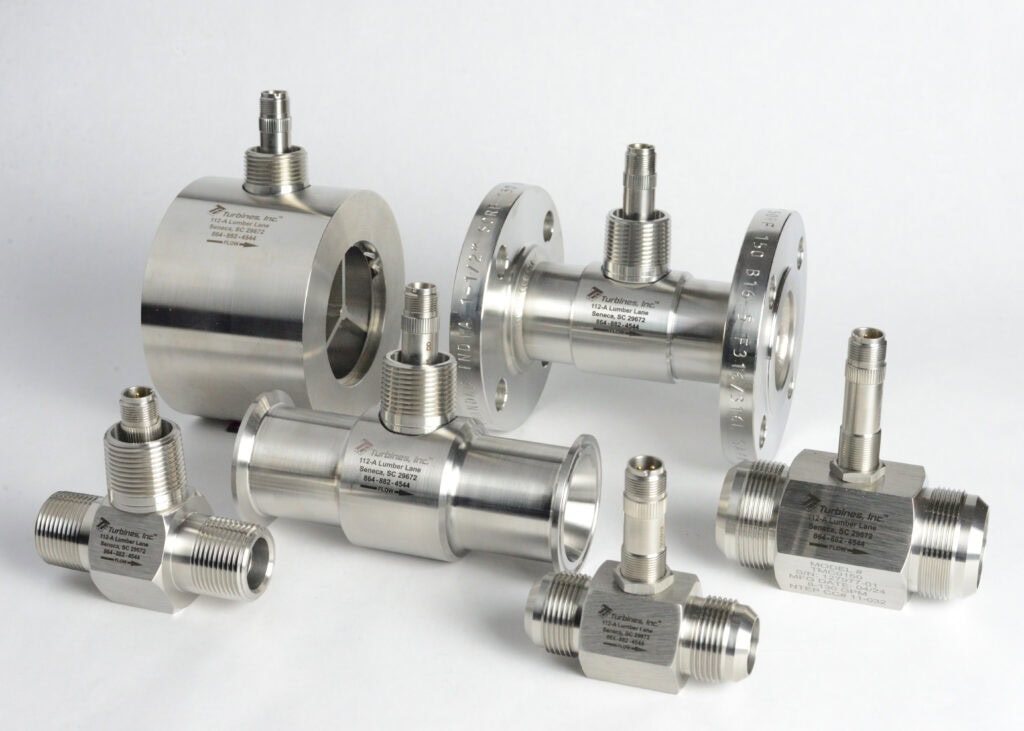

How to Size a Turbine Flow Meter for Accurate Measurement

- News

Selecting the right turbine flow meter for your application involves much more than choosing a size that matches your pipe diameter. Turbine flow meters must be sized based on the system’s actual operating conditions—especially the flow rate, pressure, temperature, and fluid characteristics. Getting the sizing right ensures optimal performance, long-term reliability, and consistent accuracy. Step…

Comparing In-Line and Clamp-On Flow Meters: Pros and Cons

- News

Flow meters play a critical role in measuring liquid flow rates across industries, from water treatment to oil and gas. Two of the most common types are in-line flow meters and clamp-on flow meters. While both serve the same fundamental purpose, they differ significantly in installation, accuracy, cost, and application suitability. This article compares their…

The Most Common Types of Gases Measured in Industrial Process

- News

What Are The Most Common Gases Metered? Accurate gas flow measurement is critical in a wide range of industries, from manufacturing and energy production to healthcare and environmental monitoring. Different gases have unique properties that require specific measurement techniques and technologies. In this blog, we’ll explore the most commonly measured gases in flow applications, their…

The Most Common Types of Water Measured by Liquid Flow Meters

- News

Water is one of the most essential resources used across a wide range of industries. From municipal water systems to agriculture and industrial processes. Liquid flow meters play an integral role in measuring the flow of water, ensuring efficiency, and meeting regulatory standards. They help operators maintain smooth operations and prevent wastage in applications where…

How Sanitary Flow Meters Improve Accuracy in Dairy Processing

- News

Dairy processing is a highly regulated industry where accuracy and hygiene are critical. Whether it’s milk, cream, yogurt, or cheese production, precise flow measurement ensures product consistency, regulatory compliance, and operational efficiency. Sanitary flow meters play a crucial role in achieving these goals, providing accurate and reliable measurement while meeting stringent hygiene standards. What Type…

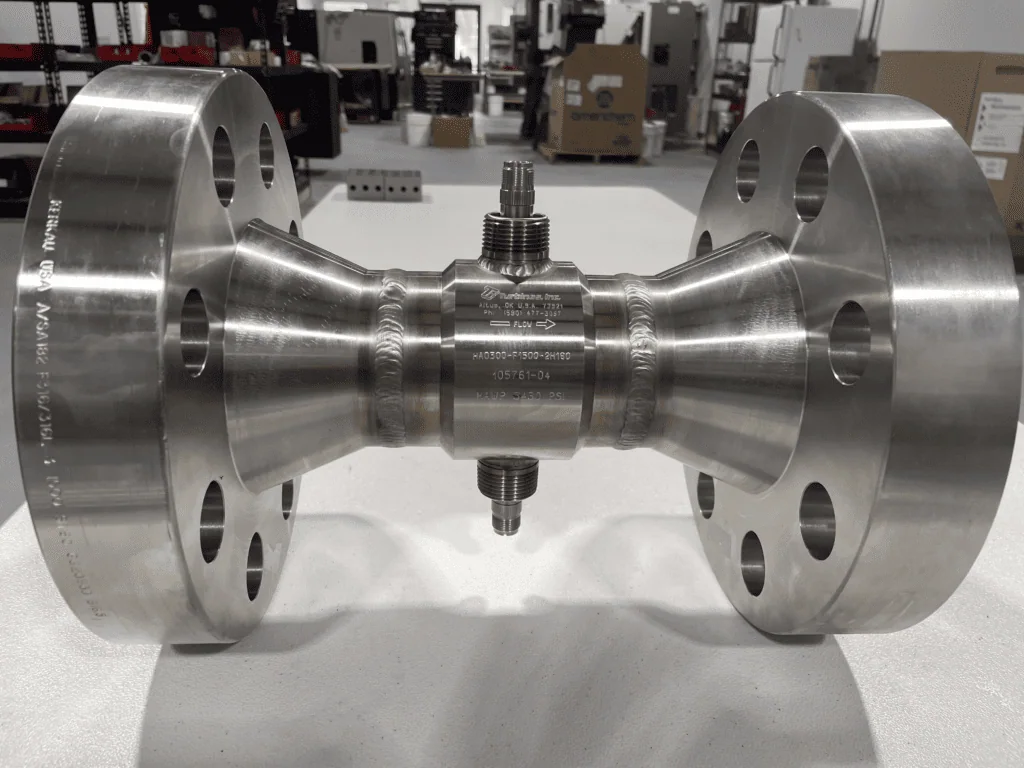

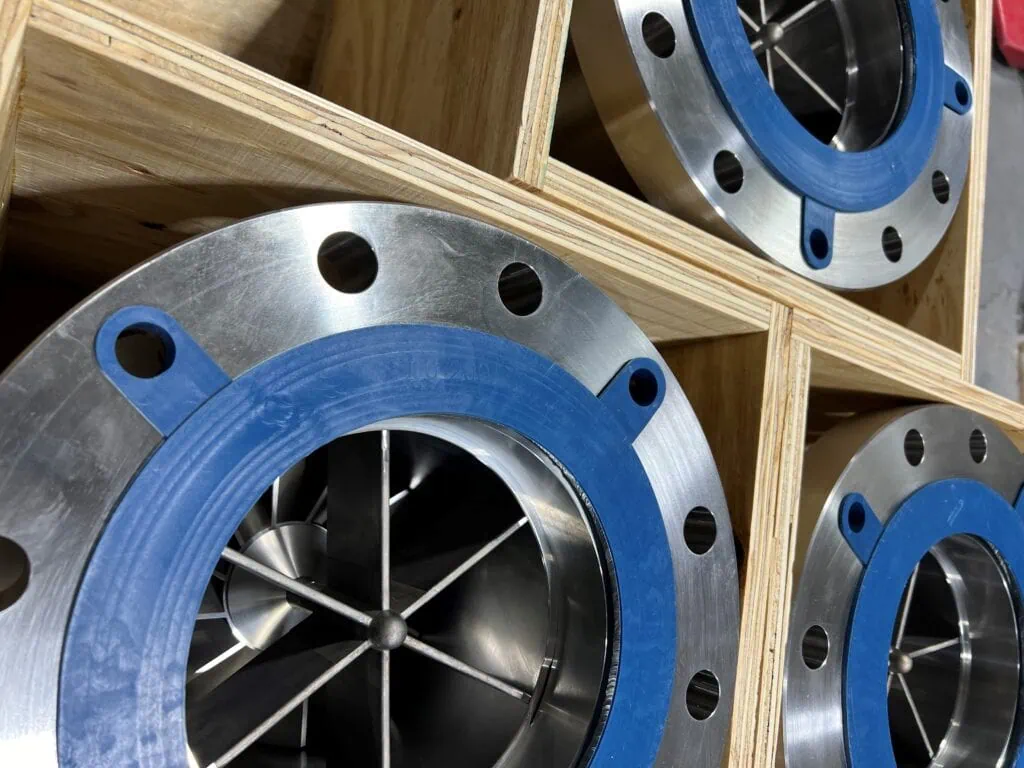

How Different End Connections Affect the Pressure Rating of Flow Meters

Choosing the right flow meter isn’t just about selecting the meter type or sizing it for specific applications. The type of end connection used on a flow meter plays a significant role in determining its pressure rating and overall performance. In many industries, whether oil and gas, chemical processing, or water management, understanding how different…