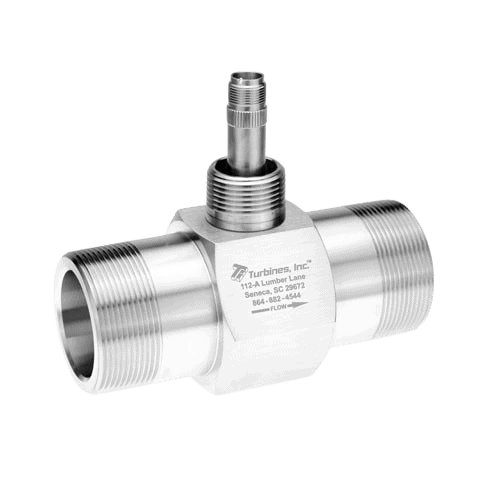

Chemical Flow Meters

Corrosive Liquids Covering Flow Ranges from 0.007 to 12,000gpm

Turbines, Inc. manufactures flow meters that are suitable for corrosive liquids such as brines, acids, and caustic fluids covering flow ranges from 0.007 to 12,000gpm. The flow data provided by these meters enables customers to optimize dosing accuracy and enhance process efficiency. Our meters offer exceptional linearity, well-engineered design, and seamless integration into existing systems, leading to reduced downtime and enhanced productivity. Each meter is provided with a NIST traceable calibration to assure optimal performance for your application.

Product Catalog

Download Our Chemical Compatibility Guide

Download The GuideNot Sure Where to Start?

We can help guide you to the correct solution for your business needs, whether you are looking for product information, data sheets, repair information we are available to help!